Main processes of hot rolling grinding balls as follows

Main processes of hot rolling grinding balls as follows

Main processes of hot rolling grinding balls as follows

1.The chemical composition range of the steel rod which is used for rolling steel ball.

2. Compression ratio of the steel rod which is after rolling.

The material detiails for producting grinding steel balls by rolling method.

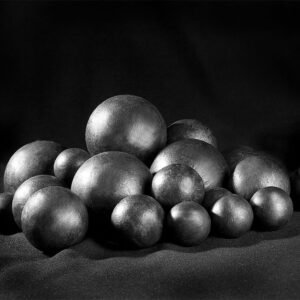

The grinding ball is a material grinding media of ball mill and coal mill. Its’ function is as an important component of ball mill under grinding and cutting effect brought by the friction between grinding balls and materials.

The provisions of this standard: The size, shape, weight and allowable deviation, technical requirements, test method, inspection rules, packing, mark and quality certificate of grinding steel ball billet.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials, and paints. Ball mills rotate around a horizontal axis, partially filled

Alloying Elements in casting ball field

Alloying Element: Any metallic element added during the making of steel for the purpose of increasing corrosion resistance, hardness, or strength. The metals used most commonly as alloying elements in chrome steel include chromium, manganese, and silicon.

Wuxi Suchuang machinery equipment manufacturing Co.Ltd

Plant Address: No. 18, Liutang Road, Hudai Town, Binhu District, Wuxi City, Jiangsu Province 214425

Office Address: No. 999, Gaolangdong Road, Binhu District, Wuxi City, Jiangsu Province 214131

Tel: 0086-150-6189-1632