The history of the heat treatment of steel ball

The history of the heat treatment of steel ball: in 1863, the British metallographer and geologists showed six different microstructure of steel under a microscope

The history of the heat treatment of steel ball: in 1863, the British metallographer and geologists showed six different microstructure of steel under a microscope

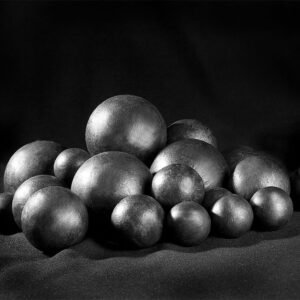

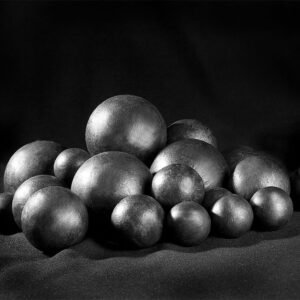

Ball mill ball can be divided into two types: forging steel balls and casting steel balls, according to the manufacturing operation.

For accurate analysis of the market situation of coal grinding machine steel industry development,

China’s domestic grade of magnetite ore is low, mostly around 10%, grinding balls while the market for iron concentrate grade must reach about 65%. So it is necessary to adopt the necessary processing equipment, processing the low-grade iron ore to high-grade iron concentrate.

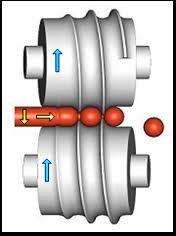

Suchuang Machinery Equipment Co., Ltd is a professional manufacturer of the automatic production line, which reduces the production cost and improves the production efficiency.

Now the mill steel ball on the market can be divided into two types according to the manufacturing process technology: Casting and forging.

Now the mill steel ball on the market according to the manufacturing process can be divided into two types: casting steel ball and forging steel ball, but the wear degree is not the same. Due to crushing, the ball needs good wear resistance and sufficient toughness, and not breaking the ball.

Wuxi Suchuang machinery equipment manufacturing Co.Ltd

Plant Address: No. 18, Liutang Road, Hudai Town, Binhu District, Wuxi City, Jiangsu Province 214425

Office Address: No. 999, Gaolangdong Road, Binhu District, Wuxi City, Jiangsu Province 214131

Tel: 0086-150-6189-1632