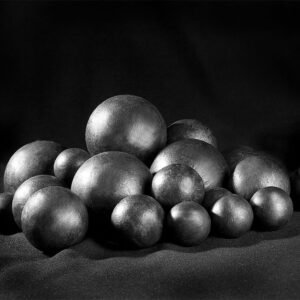

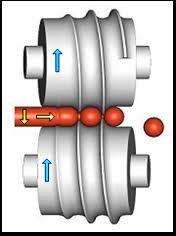

skew rolling mill for making grinding steel ball and cylpebs

After years of research and development, Suchuang Machinery successfully developed the domestic industry’s most advanced skew rolling mill(skew rolling machine)

After years of research and development, Suchuang Machinery successfully developed the domestic industry’s most advanced skew rolling mill(skew rolling machine)

Wet grinding mills work suitably with forged balls, dry grinding mills work suitably with casting balls and each kind of balls has its advantages in different working conditions.

Grinding ball material mostly are alumina and zirconia which mainly used in chemical and mechanical grinding powder, and the sample particles by grinding particle diameter is smaller.

The key factor of grinding steel ball’s lifespan decided by its manufacturing process.

One thing should be paid attention to when asked coarser grinding ball mill productivity vary with feed particle size range is more obvious, and require a finer grinding, grinding mill productivity vary with feed particle size is not too prominent.

The Collocation between steel ball and ball mill exist certain principles. So, what are these principles?

drive the workpiece rotating and moving in the against the direction, Under the action of the forging die, drawing the length of the workpiece rolling into the steel parts.

Wuxi Suchuang machinery equipment manufacturing Co.Ltd

Plant Address: No. 18, Liutang Road, Hudai Town, Binhu District, Wuxi City, Jiangsu Province 214425

Office Address: No. 999, Gaolangdong Road, Binhu District, Wuxi City, Jiangsu Province 214131

Tel: 0086-150-6189-1632