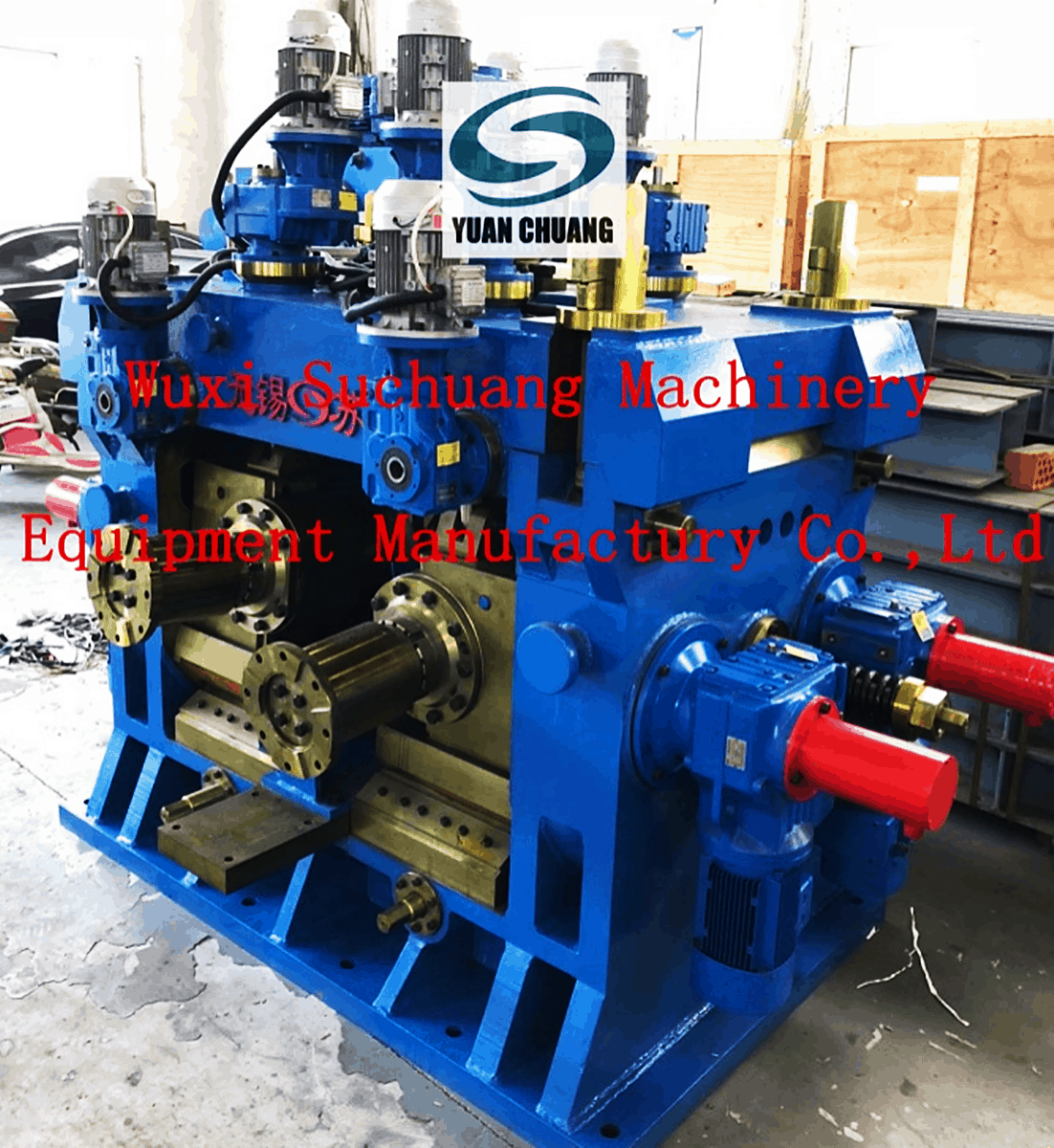

SCD60 skew rolling machine production line for grinding steel ball

Category Middle Model

Tags Cement mine steel ball, Grinding steel ball rolling

30mm to 60mm grinding steel balls could be produced on SCD60 series skew rolling mill

Additional information

| Model | SCD60 |

|---|---|

| Type | Ordinary speed, Ordinary hi-speed, Hi-speed, Ultra hi-speed |

| Ball range(mm) | Φ30 ~ Φ60 |

| Speed(balls/min) | 75 ~ 1200 |

| Productivity(t/h) | 0.90 ~ 11.98 |

Process Description

The main process of skew rolling mill:

1, After checking the round bar(material)

2, Heating the round bar up to a suitable temperature

3, Rolling the hot steel bar in the skew rolling mill, Each set of skew rolling mills can roll 40~1600 balls/min.

4, The rolled hot balls are under the quenching-tempering process.

5, Your inquiry can be customized as per your special specifications and specific requirements

Play Video

Product Details

Main features of SCD60 series skew rolling mill:

- Rack assembling: Adopting high strength, high rigidity design, high stability while continuous production

- Roller assembling: Overall roller box structure, strong bearing capacity, easy to change rollers.

- Rotating drum: adopting a large area drum design, The roller box is completely supported by a rotary drum, roller lock is stable and reliable.

- Lateral pressure adjustment: electric adjustment, Fast to adjust the hole type, And can realize dynamic adjustment,

- Top guide plate adjustment: Equipped with special electric top guide plate adjusting device, Up and down adjustment, left and right and left adjustment, left and right locking, all is electric, adjustment is fast, and locking is firm, steady running.

- Roller locking: electric locking, The labor intensity of the adjustment workers was greatly reduced

| Model | Type | Ball range(mm) | Speed(balls/min) | Productivity(t/h) |

|---|---|---|---|---|

| SCD60PT | Ordinary speed | Φ30 | 120 | 0.90 |

| SCD60PT | Ordinary speed | Φ40 | 100 | 1.78 |

| SCD60PT | Ordinary speed | Φ50 | 90 | 3.12 |

| SCD60PT | Ordinary speed | Φ60 | 75 | 4.49 |

| SCD60PG | Ordinary hi-speed | Φ30 | 360 | 3.55 |

| SCD60PG | Ordinary hi-speed | Φ40 | 200 | 3.12 |

| SCD60PG | Ordinary hi-speed | Φ50 | 90 | 4.49 |

| SCD60PG | Ordinary hi-speed | Φ60 | 75 | 1.78 |

| SCD60G | Highg speed | Φ30 | 600 | 4.49 |

| SCD60G | Highg speed | Φ40 | 340 | 6.04 |

| SCD60G | Highg speed | Φ50 | 160 | 5.55 |

| SCD60G | Highg speed | Φ60 | 100 | 5.99 |

| SCD60CG | Ultra hi-speed | Φ30 | 1200 | 8.99 |

| SCD60CG | Ultra hi-speed | Φ40 | 680 | 12.07 |

| SCD60CG | Ultra hi-speed | Φ50 | 320 | 11.10 |

| SCD60CG | Ultra hi-speed | Φ60 | 200 | 11.98 |

Note: The types are optional, productivity also can be designed according to the client’s requirement

About Skew Rolling Mill Technology Development

- Hot rolling steel ball is a new technology of skew rolling, it is the breakthrough of grinding steel balls industry’s process technology,and gradually replacing cast steel balls.

- After many years of our company’s engineers on the full research and transformation of skew rolling mill production line,Develop and manufacture the third generation hot rolling skew rolling mill production line,And has a complete set of hot-rolled steel ball production technology.

- The hot rolling skew rolling mill production line for grinding steel ball include:SCD30,SCD40,SCD50,SCD60,SCD80,SCD100,SCD120 models,It is also equipped with four types for each model: common type, common high-speed type, high-speed type and ultra high-speed type,It can produce φ20~φ125 steel balls and cylpeb,Meet the requirements of different users

The main process of skew rolling mill production line

- After checking the round bar(material) to confirm it meets the production process requirements.

- Before rolling, the round bar should be heated up to a suitable temperature in the continuous heating furnace.

- After the hot steel bar goes into the skew rolling mill, it will rotate forward between the two rollers with a special spiral groove, and continuously rolled into balls finally. Each set of skew rolling mill can roll 40~1600 balls/min.

- The rolled hot balls are under quenching-tempering process, The steel ball has high and even hardness and impact toughness.

- Our company can be according to the product specifications and specific requirements of the owner to design the optimal production line and advanced, suitable production technology.

Related products

-

SCD100 skew rolling machine production line for grinding steel ball

Read more -

SCD80 skew rolling machine production line for grinding steel ball

Read more -

SCD50 skew rolling machine production line for grinding steel ball

Read more -

SCD30 skew rolling machine production line for grinding steel ball

Read more